Hi, It's Abhay

I'm a Recent Mechanical and Digital Engineering Graduate from the University of Calgary

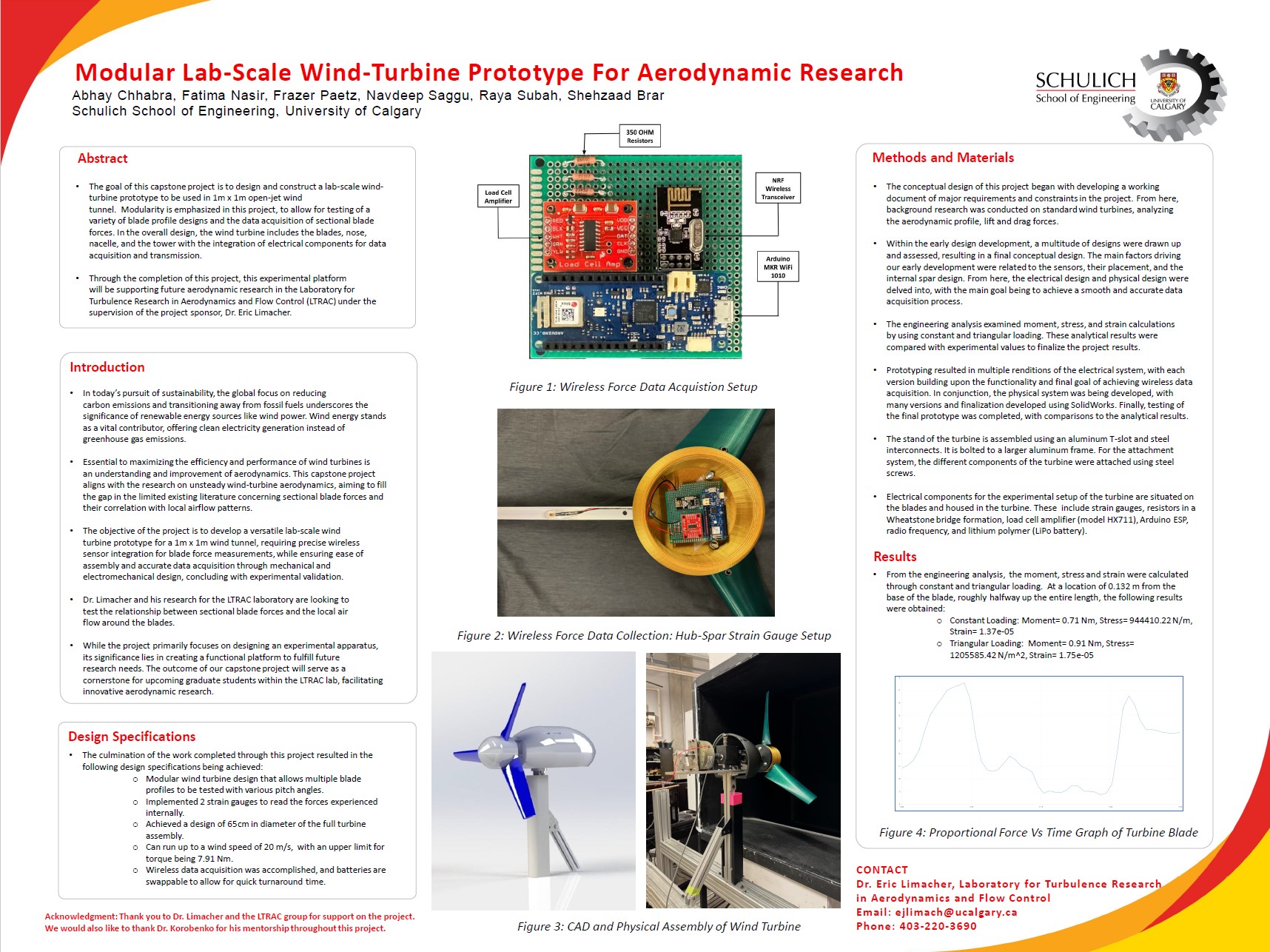

I'm a highly motivated Mechanical Engineering Graduate with a passion for innovation and sustainability. I excel in dynamic, cross functional environments , leveraging my expertise in project management and design tools like SolidWorks, Bluebeam, and Microsoft Project, alongside programming and analysis tools such as MATLAB, and Power BI. My minor in digital engineering has also equipped me with skills in Python and the application of AI and machine learning. With a solid background in Project Management and manufacturing , I am seeking new graduate positions where I can grow and embrace new opportunities.

Outside of my classes and work, you’ll likely find me watching or playing sports! I love traveling, spending time with family and friends, and trying new foods. I also enjoy exploring new hobbies; recently, I got into making videography content!