Modular Lab Scale Wind Turbine Prototype Mechanical Engineering Capstone

What?- Project Overview & Problem Statement

Dr Eric Limacher and his research on unsteady wind-turbine aerodynamics for the Laboratory for Turbulence Research in Aerodynamics and Flow Control (LTRAC) were looking to test the relationship between sectional blade forces and the local air flows around the blades. The objective of the project was to design and construct a functional and robust experimental apparatus for the comprehensive study of wind turbine aerodynamics by graduate students.

The primary goal was to develop a lab-scale wind turbine prototype for the department’s 1m x 1m open wind tunnel. The design scope includes creating a modular blade system that allows easy assembly and disassembly for testing custom 3D-printed blade designs while maintaining precision and accuracy of force measurements. An advanced wireless sensor array and telemetry system will be integrated to facilitate accurate time-resolved force data acquisition. The mechanical design of the entire rotor assembly, including the nacelle, shaft, bearings, blade mounting hardware, nose cone, and rotor braking hardware, will be developed to ensure a fully operational and balanced wind turbine prototype. A rotor-speed control algorithm will be developed and fine-tuned for precise adjustments. Additionally, a user-friendly MATLAB-based interface for data acquisition will be created to simplify the data collection process. Rigorous experimental validation will be conducted to verify the accuracy and repeatability of the force-measurement system.

How?- Theory and Conceptualization

Several turbine designs were conceptualized and sketched for prototyping, with the mechanical and electrical principles for calculating system thrust, drag, power draw, and nominal voltage serving as fixed theoretical baselines. I was responsible for performing these Mechanical & Electrical Systems Design calculations, validating them against experimental data, and ensuring seamless integration of all electrical components into the turbine system.

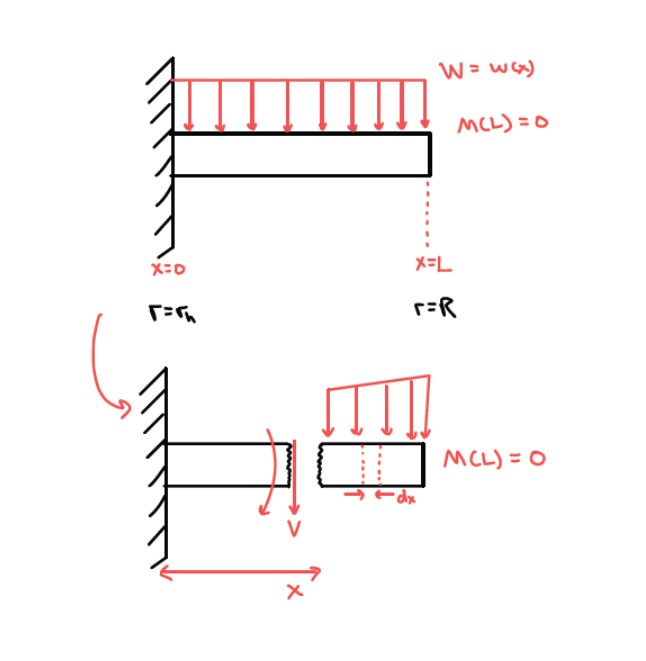

On the mechanical side, I applied fluid mechanics to calculate power, torque, and aerodynamic forces on the blades using given coefficients, used fundamental beam theory from deformations of solids to determine moment, stress, strain, and tip deflection, and iterated from a square to a triangular spar geometry for structural efficiency. I also calculated drag on the system tower to ensure it contributed less than 5% of total system drag.

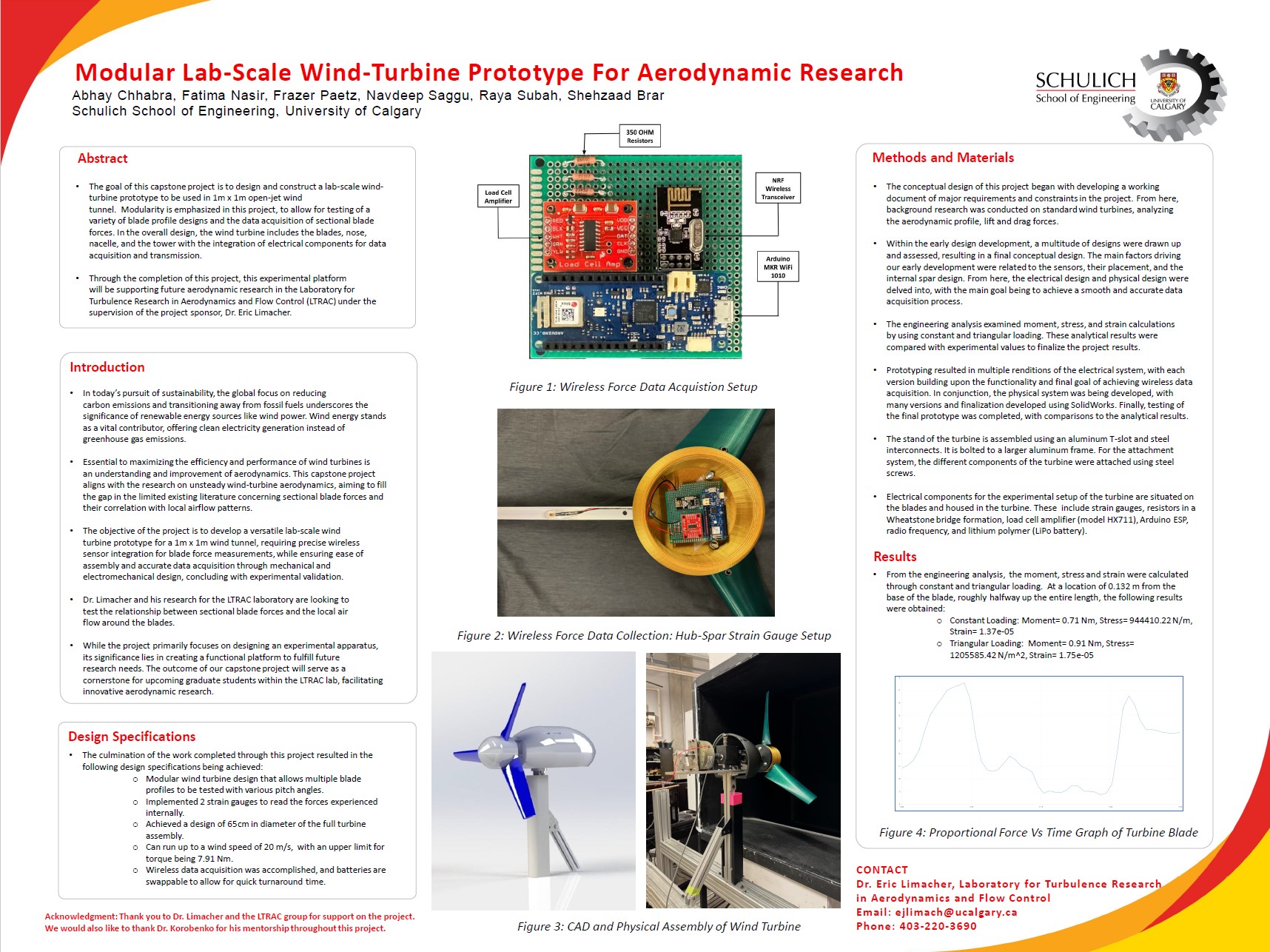

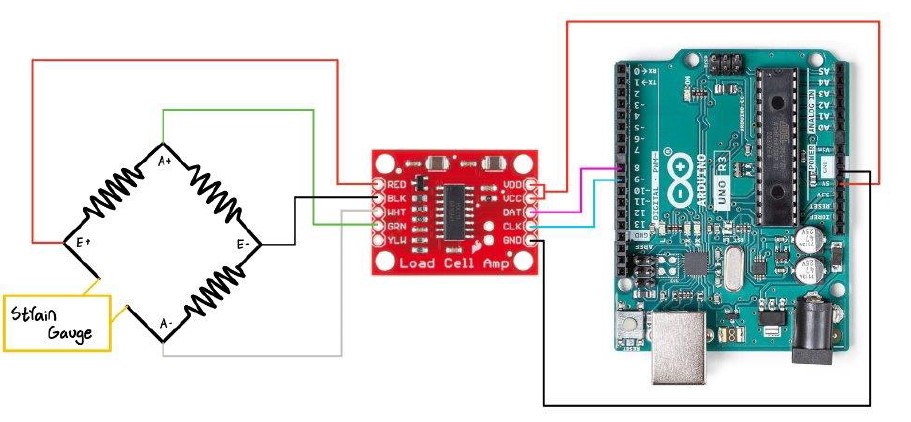

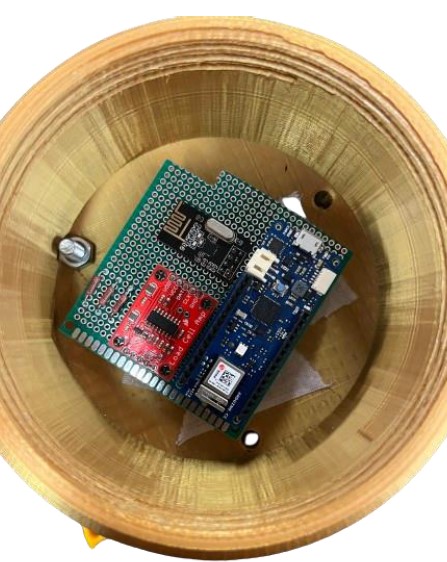

For the electrical system, I researched and selected optimal components, using Ohm’s Law and electrical power equations to determine total system power draw and match it with an appropriate battery and voltage requirements. I compared sensor technologies using decision matrices, ultimately selecting strain gauges, and integrated them with a wireless data acquisition system (Wheatstone bridge, load cell amplifier, Arduino ESP, and NRF radio) to measure sectional blade forces in real time.

This project integrated advanced mechanical analysis with electrical system design, resulting in a modular, high-precision research platform for future aerodynamic studies.

Results- Physical Prototype and Validation

Final Prototype and Testing

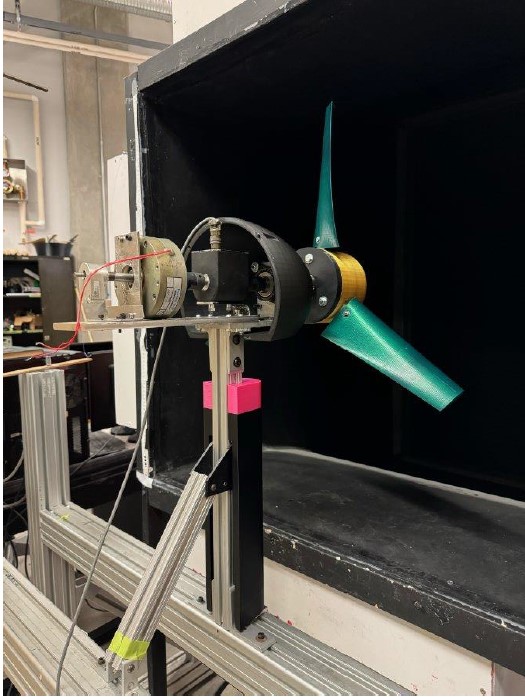

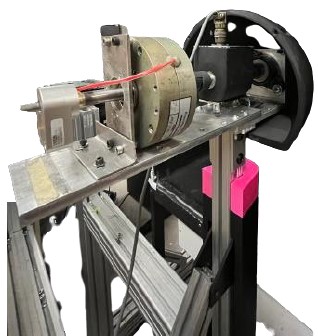

Our final prototype is a modular, lab-scale wind turbine, specifically designed for use within a 1m x 1m open-jet wind tunnel. The turbine assembly measures 65 cm in diameter and features a modular design that facilitates the testing of various blade profiles and pitch angles. The structural stand is constructed from aluminum T-slot and steel interconnects, securely bolted to a larger aluminum frame.

The turbine's electrical system is integrated within the blades and nacelle, enabling wireless data acquisition. Key electrical components include:

- Two strain gauges.

- Resistors configured in a Wheatstone bridge formation.

- An HX711 load cell amplifier.

- An Arduino MKR WIFI 1010.

- An NRF wireless transceiver.

- A swappable lithium polymer (LiPo) battery, ensuring quick turnaround times.

Testing and Results

The performance of the final prototype was rigorously validated through experimental testing and comparison with analytical calculations. The turbine is capable of operating efficiently at wind speeds up to 20 m/s. Engineering analysis of the turbine blade, considering both constant and triangular loading conditions, yielded calculated values for moment, stress, and strain. At a specific location 0.132 m from the base of the blade, the following analytical results were obtained:

- Constant Loading: Moment was calculated at 0.71 Nm, stress at 944,410.22 N/m$^2$, and strain at 1.376-05.

- Triangular Loading: Moment was calculated at 0.91 Nm, stress at 1,205,585.42 N/m$^2$, and strain at 1.756-05.

A significant achievement of this project was the successful implementation of wireless data acquisition, which was a core objective for the experimental platform. The prototype exhibits an upper torque limit of 7.91 Nm.

Tools, Technologies & Key Learnings

Tools & Technologies Used:

- Machine Shop Tools

- Solidworks

- Matlab

- Python

- fundamental Beam Theory

Key Learnings & Skills Developed:

- Project Managment

- Stress Analysis

- Rapid Prototyping